C-GEN is made up of light weight stator and rotor modules, arranged as shown in the figure below for a rotary machine.

The smallest single C-GEN module consists of a single c-core with magnets mounted in the inside surface as shoiwn. These c-cores can be arranged around the circumference and in the axial direction to produce an axial flux multi-stage machine, with 6 stages shown in the example. A rotor module can be made up of any number of c-cores, but the dimensions are chosen with manfacture, assembly and transport as the key drivers. A single permanent magnet rotor module is shown in the figure below. Rotor modules have been cast as a single piece or made up of plates bolted together, with both methods being successfully proved.

Concentrated coils are supported in non-magnetic material, epoxy potting compounds can be used. A number of coils are potted into a mould to form a so-called stator blade. The figure below show 6 coils in a stator blade, with blades being assembled around the circumference of the machine to make up a single stage. Stages can then be mounted in the axial direction to make up any size of machine. For example in the 1 MW demonstrator there were 4 stages, with each stage rated at 250 kW. Since the stator coils are supported in a non-magnetic material there are no electromagnetic attraction forces between the coils and the magnets during assembly and operation, which is typical of so-called air-cored windings.

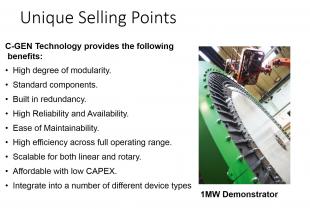

The modular approach along with the air-cored windings has significant benefits in terms of component manufacture and final assembly. The lack of magnetic attraction forces between stator coils and permanent magnet rotor has benefits in the structural and bearing design, as the structural loads are reduced. The low generator and module weight of the C-GEN technology reduces O&M costs compared to traditional iron-cored, radial flux PMG systems. The maintenance of drive train components, if necessary, can be carried out with lighter lifting equipment or an internal turbine crane. Multiple generators consisting of simple, lightweight modules can be “stacked” back-to-back along the shaft of a wind turbine to create a multi-MW rating without increasing the machine diameter. This means that for certain generating system line failures, one generator line can be isolated, enabling the wind turbine to continue generating revenue whilst maintenance is scheduled. This redundancy characteristic is even more relevant for remote areas with challenging conditions for access, e.g. offshore wind farms. In C-GEN the number of generators in operation can be adjusted based on wind conditions to optimise the power output, efficiency and increase longevity. In conventional PMGs magnets try to align themselves with steel teeth onto the stationary part of the generator and cogging torque will result in overcoming this alignment force. This characteristic increases the cut-in wind speed (the minimum wind speed at which the turbine produces power) and creates vibrations in the generator. C-GEN does not have any cogging torque to overcome (there is zero cogging torque as there is no iron in the stator), and can thus generate power at low wind speeds and do not create vibrations in the generator, which can also reduce noise. The unique selling points are summarized below.

A short power point presentation with further details can be downloaded below.